-40%

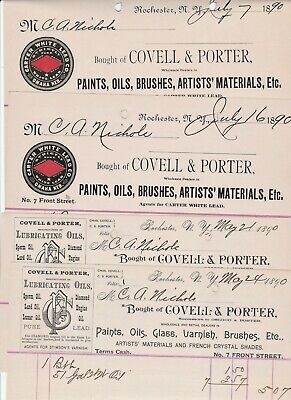

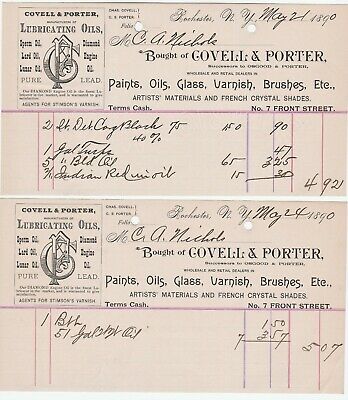

RARE 4 Billheads - Carter White Lead Paint Omaha Covell Porter Rochester NY 1890

$ 20.06

- Description

- Size Guide

Description

NICE OriginalB

illhead

LOT

4 Pieces

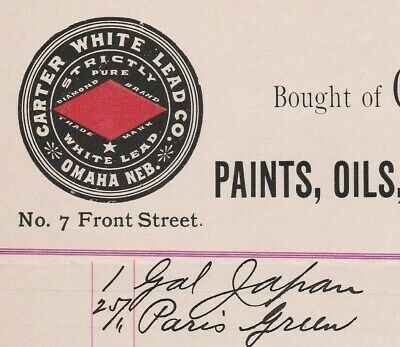

Carter White Lead - Omaha Neb.

Covell & Porter - Paints, Oils, Brushes, etc - Rochester, NY

1890

For offer, a very nice old Advertising engraved / lithograph design lot! Fresh from an old prominent estate. Never offered on the market until now.

Vintage, Old, Original -

NOT

a Reproduction - Guaranteed !!

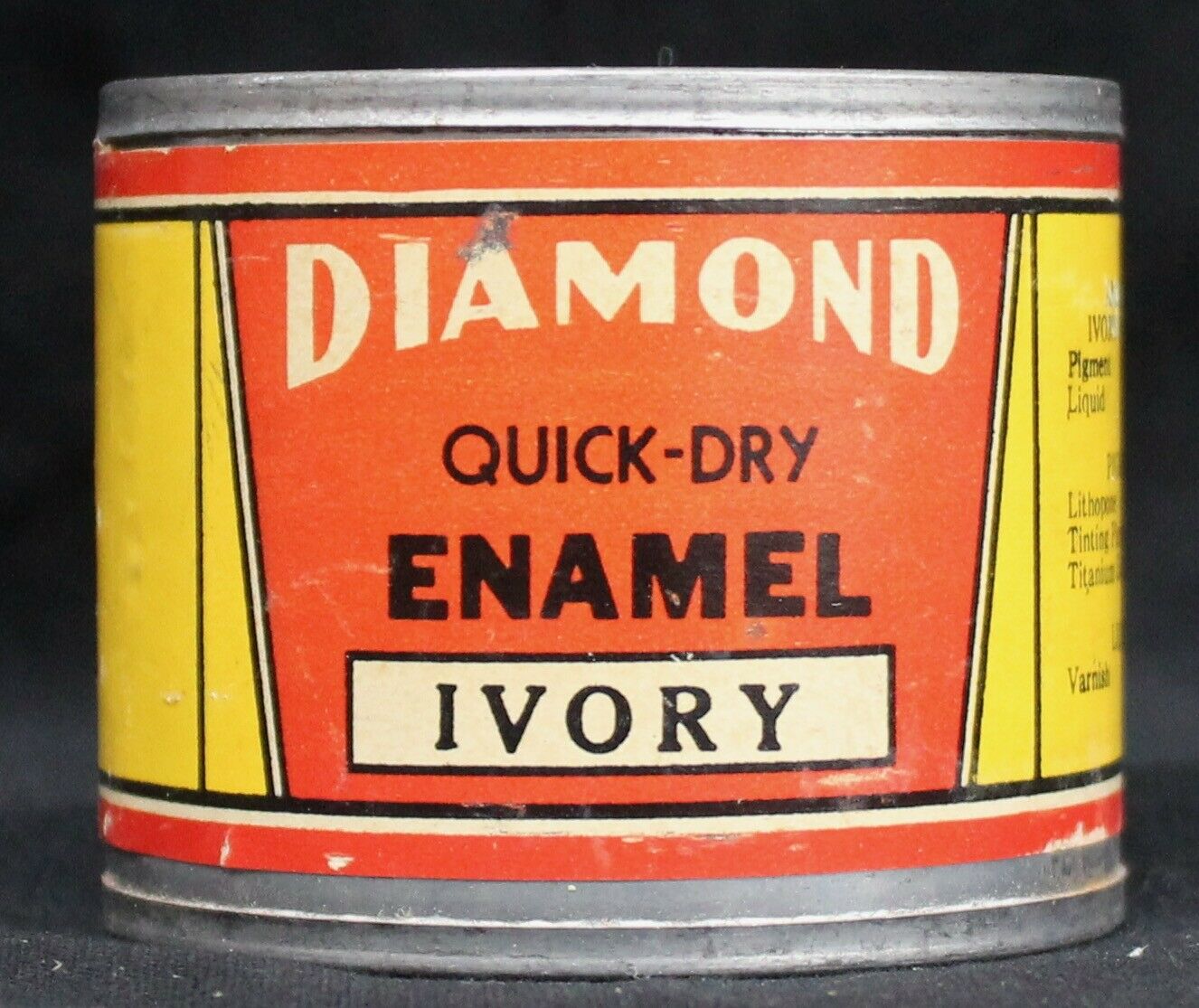

Nice graphic printing - color - red & black - for Carter Diamond Brand Lead Paint, Omaha, Nebraska. This company made the paint for the White House in Washington D.C. Billheads for Covell & Porter, Rochester, New York - paints, oils, brushes, artists materials. Also Frensh crystal shades. With manuscript handwriting, signed / signatures, autograph letter, etc. To C.A. Nichols, Chili, NY. In

good to very good condition. Fold marks. NOTE: Items will be shipped folded, as found - to save on shipping. Please see photos and scans for all details and condition.

If you collect 19th century Americana advertisement ad history, United States of America printing, American history, etc. this is a nice one for your paper or ephemera collection. Genealogy research importance as well. Combine shipping on multiple bid wins! 2104

Nearby towns in Monroe County :

City

Rochester (county seat)

Towns

Brighton

Chili

Clarkson

East Rochester

Gates

Greece

Hamlin

Henrietta

Irondequoit

Mendon

Ogden

Parma

Penfield

Perinton

Pittsford

Riga

Rush

Sweden

Webster

Wheatland

Villages

Villages in New York State are incorporated municipalities located within Towns. The town in which each village is located is noted in parenthesis.

Brockport (Sweden)

Churchville (Riga)

East Rochester (Coterminous village and town)

Fairport (Perinton)

Hilton (Parma)

Honeoye Falls (Mendon)

Pittsford (Pittsford)

Scottsville (Wheatland)

Spencerport (Ogden)

Webster (Webster)

Census-designated places

Brighton

Clarkson

Gates

Greece

Hamlin

Irondequoit

North Gates

Hamlets

In New York State the term "Hamlet", although not defined in law, is used to describe an unincorporated community and geographic location within a town. The town in which each Hamlet is located is in parenthesis.

Egypt (Perinton)

Adams Basin (Ogden)

Bushnell's Basin (Perinton)

Gates Center (Gates)

Garbutt (Scottsville)

Mumford (Wheatland)

Union Hill (Webster)

Mendon Center (Mendon)

Seabreeze (Irondequoit)

Summerville (Irondequoit)

Parma Center (Parma)

Riga Center (Riga)

Sweden Center (Sweden)

West Webster (Webster)

North Chili (Chili)

Clarkson Corners (Clarkson)

Gates Center (Gates)

North Gates (Gates)

Clifton (Chili)

Industry (Rush)

Belcoda (Wheatland)

The Omaha White Lead Works were established by W.A. Paxton, Levi Carter, C. Hartman, W.B. Royal, C.W. Mead, N. Shelton, D.O. Clarke, and S.E. Lock in August of 1878 with a capacity of 600 tons a year and capital of ,000. The plant was built at 20th Street and the Union Pacific tracks. At the time of its establishment, it was the largest white lead works west of St. Louis.

In 1881 the capacity was increased to 1200 tons a year and the capital to ,000. The low price of lead in 1885 forced the plant to shut down in that year. Until then the process of making white lead was known as the "Dutch process." Sheets of lead were placed in vats where they underwent an extensive and time-consuming corroding process. Levi Carter, freighter and cattleman, experimented with a new process whereby the lead was reduced to atoms instead of being allowed to remain in large sheets. The corroding process then took a comparatively small amount of time.

Carter reorganized the company in 1886 under the name Carter White Lead Works. The capital was set at 0,000 but was increased to 0,000 in 1889. The capacity of the plant reached 4000 tons as Carter's new atomizing process proved that better white lead could be produced at a smaller cost and in less time than by the old process.

On June 14, 1890, the lead works plant was destroyed by fire. Before year's end, a new 0,000 plant had been constructed in East Omaha and within a couple of years the plant's output reached 7000 tons. Under Carter's management, the company became the largest corroder of white lead in the U.S., with factories in Omaha and Chicago. The Chicago plant was the largest single white lead factory in the world.

Levi Carter died on November 7, 1903. Five years after his death, the Carter White Lead Company still claimed to be the largest independent manufacturer of lead in the U.S., with a capital of 0,000, and a yearly capacity of 30,000 tons.

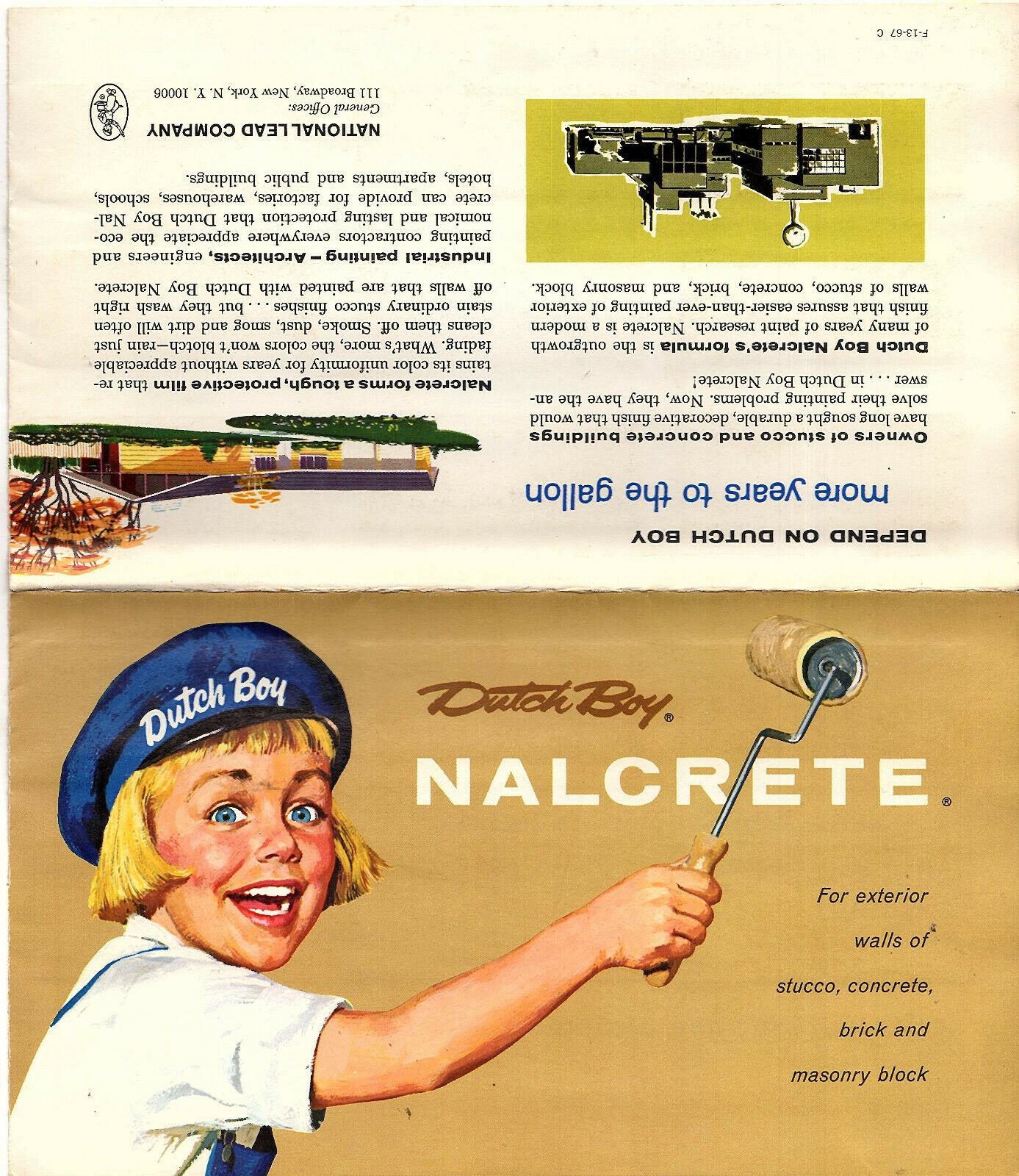

The Carter White Lead Company dissolved in 1936. All of its property was distributed to the National Lead Company, which was headquartered in New Jersey. The new owner continued to operate the Chicago plant as the Carter Brand of the National Lead Company.

Lead paint or lead-based paint is paint containing lead. As pigment, lead(II) chromate (PbCrO4, "chrome yellow"), Lead(II,IV) oxide, (Pb3O4, "red lead"), and lead(II) carbonate (PbCO3, "white lead") are the most common forms.[1] Lead is added to paint to accelerate drying, increase durability, maintain a fresh appearance, and resist moisture that causes corrosion. It is one of the main health and environmental hazards associated with paint. In some countries, lead continues to be added to paint intended for domestic use,[2] whereas countries such as the U.S. and the UK have regulations prohibiting this, although lead paint may still be found in older properties painted prior to the introduction of such regulations. Although lead has been banned from household paints in the United States since 1978, paint used in road markings may still contain it. Alternatives such as water-based, lead-free traffic paint are readily available, and many states and federal agencies have changed their purchasing contracts to buy these instead.

History

Lead white was being produced during the 4th century BC; the process is described by Pliny the Elder, Vitruvius and the ancient Greek author Theophrastus.

The traditional method of making the pigment was called the stack process. Hundreds or thousands of earthenware pots containing vinegar and lead were embedded in a layer of either tan bark or cow dung. The pots were designed so that the vinegar and lead were in separate compartments, but the lead was in contact with the vapor of the vinegar. The lead was usually coiled into a spiral, and placed on a ledge inside the pot. The pot was loosely covered with a grid of lead, which allowed the carbon dioxide formed by the fermentation of the tan bark or the dung to circulate in the pot. Each layer of pots was covered by a new layer of tan, then another layer of pots. the heat created by the fermentation, acetic acid vapor and carbon dioxide within the stack did their work, and within a month the lead coils were covered with a crust of white lead. This crust was separated from the lead, washed and ground for pigment. This was an extremely dangerous process for the workmen. Medieval texts warned of the danger of "apoplexy, epilepsy, and paralysis" from working with lead white.[3]

Despite the risks, the pigment was very popular with artists because of its density and opacity; a small amount could cover a large surface. It was widely used by artists until the 19th century, when it was replaced by zinc white and titanium white.[4]

The dangers of lead paint were considered well-established by the beginning of the 20th century. In the July 1904 edition of its monthly publication, Sherwin-Williams reported the dangers of paint containing lead, noting that a French expert had deemed lead paint "poisonous in a large degree, both for the workmen and for the inhabitants of a house painted with lead colors".[5] As early as 1886, German health laws prohibited women and children from working in factories processing lead paint and lead sugar.[6] In 1786, Benjamin Franklin wrote a letter warning a friend about the hazards of lead and lead paint, which he considered well-established.[7]

The League of Nations began efforts to ban lead paint in 1921.[8][9]

Toxicity

Further information: Lead poisoning

Lead paint can crack and form flakes, which then contaminate the surrounding environment.

Lead paint is hazardous. It can cause nervous system damage, stunted growth, kidney damage, and delayed development.[10] It is dangerous to children because it tastes sweet, therefore encouraging children to put lead chips and toys with lead dust in their mouths. Lead paint is dangerous to adults and can cause reproductive problems in men or women. Decreases in sperm production in men have been noted. Lead is considered a possible and likely carcinogen. High levels may result in death.

Regulation

Globe icon.

The examples and perspective in this section deal primarily with the United States and do not represent a worldwide view of the subject. You may improve this section, discuss the issue on the talk page, or create a new article, as appropriate. (May 2012) (Learn how and when to remove this template message)

Lead paint is banned in the European Union by the 2003 Restriction of Hazardous Substances Directive (RoHS), which forbids hazardous substances in consumer goods, including paint. This act superseded and harmonized existing laws of the member states, many of which had banned lead paint years before.

To protect the painters' health, France had already passed in 1909 a law banning the use of paints containing lead for the painting of the interior and exterior of all buildings.[11]

In Canada, regulations were first enacted under the Hazardous Products Act in 1976 that limited lead content of paints and other liquid coatings on furniture, household products, children's products, and exterior and interior surfaces of any building frequented by children to 0.5% by weight.[12] New regulations on surface coating materials, which came into force in 2005, further limit lead to its background level for both interior and exterior paints sold to consumers. Canadian paint manufacturers have been conforming to this background level in their interior and exterior consumer paints since 1991.[13] Nevertheless, a Canadian company, Dominion Colour Corporation, is "the largest manufacturer of lead-based paint pigments in the world" and has faced public criticism for obtaining permission from the European Chemicals Agency to continue to export lead chromate paints from its Dutch subsidiary to countries where its uses are not tightly regulated.[14]<[9]

The United States' Consumer Product Safety Commission (CPSC) banned lead paint in 1977 in residential properties and public buildings (16 CFR 1303), along with toys and furniture containing lead paint. The cited reason was "to reduce the risk of lead poisoning in children who may ingest paint chips or peelings".[15] For manufacturers, the CPSC instituted the Consumer Product Safety Improvement Act of 2008, which changed the cap on lead content in paint from 0.06% to 0.009% starting August 14, 2009. In 2018 the State of Delaware banned the use of lead paint on outdoor structures.[16] Also, the Residential Lead-Based Hazard Reduction Act (AKA the "Lead Paint Act") was created in order to ensure that the disclosure of any lead-based hazards in a building be discussed with potential buyers or renters of units.[17][18]

In April 2010 the U.S. Environmental Protection Agency required that all renovators working in homes built before 1978 and disturbing more than six square feet of lead paint inside the home or 20 square feet outside the home be certified. EPA's Lead Renovation, Repair and Painting Rule (RRP Rule) lowers the risk of lead contamination from home renovation activities. It requires that firms performing renovation, repair, and painting projects that disturb lead-based paint in homes, child care facilities and pre-schools (any child occupied facility) built before 1978 be certified by EPA and use certified renovators who are trained by EPA-approved training providers to follow lead-safe work practices.[19]

As of 2018, there are an estimated 37 million homes and apartments with lead paint in the United States.[20]

The Philippines banned lead paint in 2013, but in 2017, 15% of the paint still was not certified.[21]

Lead paint is not prohibited in India. A 2015 study found that over 31% of household paints in India had lead concentration above 10,000 parts per million (ppm), which far exceeds the BIS standard of 90 ppm for lead in paint.[22]

In South Africa, the Hazardous Substances Act of 2009 classifies lead as a hazardous substance and limits its use in paint to 600 parts per million (ppm). A proposed amendment will modify this to 90 ppm, thereby almost completely eradicating lead from paint. The amendment would also include all industrial paints, which were previously excluded.[23]

Lead paint in art

Oil paints

In art, white lead paint is known as "flake white" or "Cremnitz white". It is valued for the ease of handling and resilience the lead confers to oil paints. Lead white paint dries relatively quickly to form a strong, flexible paint film. Lead-based white is one of the oldest manufactured pigments. It was the only white pigment available to artists in appreciable quantities until the twentieth century, when zinc-white and titanium-white became available.[24] Industrially produced lead white, the typical pigment from the 19th century until its ban, was thought to be inferior to traditionally fabricated forms, which had larger "flake" particles that conferred ease of handling.

Titanium and zinc whites are far less toxic than lead white and have largely supplanted it in most fine arts applications. Safety regulations have also made lead white more expensive and difficult to obtain in some regions, such as the EU. However, lead white oil paints are still produced and in use by artists who prefer their unique handling, mixing, and structural qualities.[24]

Flake white has various drawbacks, including a tendency to become transparent over time. It also blackens in the presence of certain atmospheric pollutants, although this can be reversed.

Water-based paints

Lead is not a traditional pigment in water media, as zinc is superior for works on paper, as is calcium hydroxide (slaked lime) for frescos. Lead-based paints, when used on paper, often cause the work to become discolored after long periods of time; the paint's lead carbonate reacts with hydrogen sulfide in the air and with acids, which often come from fingerprints.[25]

Substitutes

Titanium

Paint manufacturers have replaced white lead with a less toxic substitute, titanium white (based on the pigment titanium dioxide), which was first used in paints in the 19th century. Titanium dioxide is considered safe enough to use as a food coloring and in toothpaste. It is also a common ingredient in sunscreen. When used in paints today, it is often coated with silicon or aluminum oxides for durability. Titanium white has far greater opacity and tinting strength than lead white, and it can easily overpower most other pigments if not mixed carefully. Titanium white has been criticized for leading to "chalkiness" in mixtures, and for allegedly decreasing the permanence of organic pigments mixed with it due to its high refractive index.

Zinc

Zinc white is less opaque and weaker in tinting strength than either titanium white or lead white. It is commonly used to lighten mixtures subtly while maintaining transparency. Although zinc white is the standard white in watercolors, its structural soundness in oils has been debated. Zinc white dries slowly and creates a relatively inflexible paint film. Critics of the pigment argue that its use leads to excessive cracking and delamination, even when used sparingly.[26]

See also

Environmental issues with paint

Lead-based paint in the United Kingdom

Lead-based paint in the United States

Lead tetroxide

Lead–crime hypothesis